Navigating Regulatory Compliance in the Oil Pump Manufacturing Industry

Regulatory compliance is a pressing concern for businesses in the oil pump manufacturing industry. Ensuring adherence to local, national, and global standards is a legal obligation and a critical driver of business success. From environmental laws to workplace safety regulations, the compliance landscape is complex, with continuous updates that demand attention and action from manufacturers.

Regulatory compliance is a pressing concern for businesses in the oil pump manufacturing industry. Ensuring adherence to local, national, and global standards is a legal obligation and a critical driver of business success. From environmental laws to workplace safety regulations, the compliance landscape is complex, with continuous updates that demand attention and action from manufacturers.

This blog will explore key compliance challenges that oil pump manufacturers face, provide actionable steps to address these issues, and highlight the importance of staying ahead of regulatory changes to maintain a competitive edge.

The Regulatory Landscape for Oil Pump Manufacturers

Why Compliance Matters

For oil pump manufacturers, compliance impacts more than legal standing; it affects reputation, profitability, and marketability. Regulatory frameworks ensure safe operations, ethical labor practices, and environmentally responsible production processes. Non-compliance can lead to heavy fines, operational delays, and loss of trust with partners and clients.

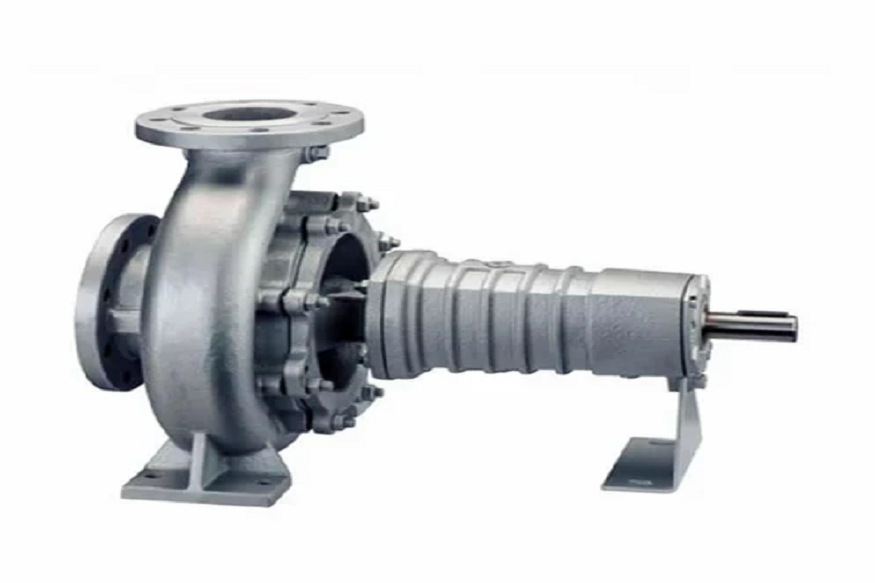

For example, manufacturers producing oil gear pumps for industrial use must ensure their products meet safety and efficiency standards to avoid equipment malfunctions that could lead to environmental damage.

Key Regulatory Areas to Address

- Environmental Standards: Stringent guidelines, such as those set by the Environmental Protection Agency (EPA) in the United States and the European Union’s REACH regulation, govern emissions, waste disposal, and material sourcing.

- Product Safety Standards: Compliance with international certifications like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) is often a prerequisite for global markets.

- Workplace Safety Regulations: Organizations like OSHA in the U.S. enforce safety practices to prevent workplace injuries. Oil pump manufacturers dealing with heavy machinery must align their safety protocols with these regulations.

- Export and Trade Compliance: For manufacturers operating internationally, compliance with trade laws, such as customs regulations and anti-dumping laws, is essential.

Challenges in Regulatory Compliance

Meeting regulatory demands can be a daunting task for manufacturers due to the following challenges:

Frequent Updates and Changes

Regulatory standards are constantly evolving, making it imperative for oil pump manufacturers to stay informed about new compliance requirements. For instance, revisions to environmental protection laws can impact the raw materials used in oil gear pump manufacturing. Staying unaware could lead to non-compliant practices and hefty penalties.

Global Compliance Complexities

Manufacturers operating across borders face a more intricate regulatory framework. Each country has unique requirements, creating challenges in ensuring that a single product complies with multiple jurisdictions.

Cost and Resource Allocation

Implementing compliance measures often demands investment in advanced equipment, regular audits, and skilled compliance teams. For small and mid-sized oil pump manufacturers, these costs can strain budgets and resources.

Practical Steps to Ensure Compliance

Adopting proactive measures can help oil pump manufacturers effectively manage regulatory obligations while optimizing operations. Here’s a step-by-step approach to achieving compliance.

Establish a Compliance Team

Form a dedicated team to monitor regulatory changes and ensure adherence. This team should include professionals well-versed in environmental, workplace, and product safety regulations relevant to the oil pump industry.

Conduct Regular Audits

Routine auditing of production processes helps identify non-compliance risks and opportunities for improvement. Audits also act as a buffer, providing time to address gaps before they escalate into bigger issues.

Invest in Advanced Technology

Leverage modern tools like compliance management software to track and document adherence to standards in real time. Additionally, advanced manufacturing technologies, such as 3D printers and automated quality checks, can help produce consistent, regulation-compliant oil gear pumps.

Foster Strong Supplier Relationships

Partner with suppliers who prioritize compliance themselves. For example, sourcing materials from certified eco-friendly providers ensures adherence to environmental standards from the ground up.

Stay Updated with Industry Regulations

Subscribe to industry publications, participate in educational webinars, or join professional associations designed for oil pump manufacturers. These resources provide valuable updates on evolving regulatory trends.

The Business Benefits of Compliance

Far from being just a legal necessity, regulatory compliance offers several significant benefits for oil pump manufacturers, including optimized workflows, reduced risk, and enhanced credibility.

- Gain Market Access: Manufacturers that align with international standards often gain greater access to lucrative global markets that demand strict certifications.

- Improve Brand Reputation: Compliance amplifies trust and credibility among stakeholders, helping reinforce business-client relationships.

- Avoid Costs of Non-compliance: Fines, legal fees, and production halts resulting from regulatory violations often cost more than investing in preventive measures.

- Encourage Workplace Morale: A compliant workplace often means a safer and more organized environment, leading to improved employee morale and productivity levels.

Compliance as a Competitive Advantage

Focusing on regulatory compliance in the oil pump manufacturing industry is not just about avoiding penalties. It’s about aligning with industry best practices to remain relevant, competitive, and future-proof. Businesses that prioritize compliance signal to customers, partners, and investors that they are reliable and forward-thinking.

By adopting proactive measures, oil gear pump manufacturers can not only ensure adherence to standards but also innovate sustainably, scale globally, and build a resilient brand in a highly competitive industry.